One of the most critical aspects of metal fabrication is the capacity to form and shape the metal parts combined with the ability to cut the metal material to make it suit the specific needs of the project. This is where metal cutters enter the picture.

Metal is among the toughest materials ever harnessed, created, and improved on the face of the planet. That’s why it’s not a big surprise that numerous special tools were also developed to cut metal.

Today, you can find and choose from a myriad of tools for cutting metal, either machine or manual-operated. But to make it easier for you to make the choice when it’s finally time to use these tools, it’s important to be familiar with their different types.

Below are the primary types of metal cutting tools you can consider to use to fabricate metal components for your future projects.

Table of Contents

What are Metal Cutters?

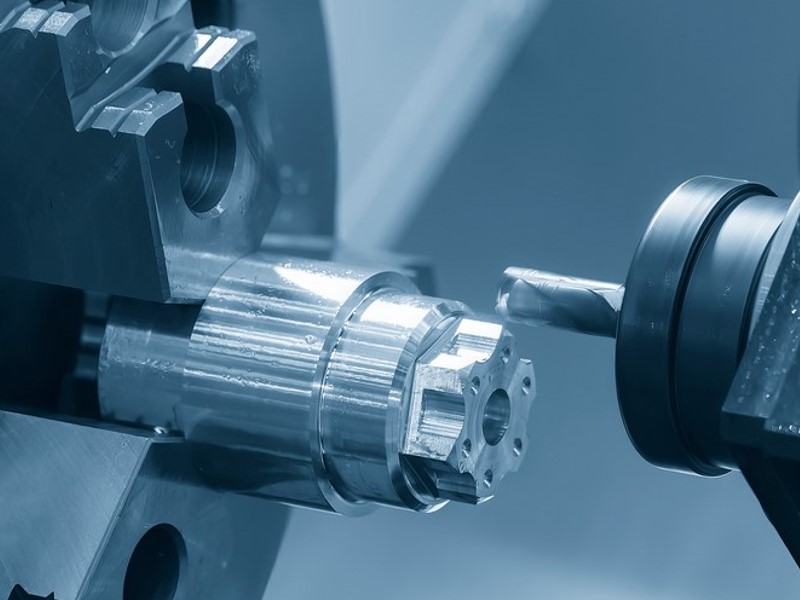

Metal cutting tools have a critical role to play in the manufacturing industry. These tools include machining equipment that cuts, drills, grinds, presses, punches, and shears. Machine tools are power-driven metal forming or cutting machines used for changing workpieces into specified shapes and sizes by cutting away unwanted sections.

These tools also carry out controlled electrical machinery processes such as shearing, pressing, sealing, and drawing. Metal cutting tools are also operated either with automatic control or manually.

Types of Metal Cutting Tools

You can find different types of machine tools in the market, which include thick metal cutting tools, handheld metal cutting tools, and more.

The machines that can cut metal include machining centres, grinding machines, boring machines, millers, drilling machines, and lathes.

The main purpose of metal cutters is to get rid of leftover materials from a manufactured metal piece with the use of shear deformation.

Metal cutting tools have two primary types that are often used these days, namely multi-point and single-point tools.

Multi-point tools might be a part of critical processes such as milling, drilling, and grinding, while single-point tools are mostly used to remove excess material by cutting the edges through turning, shaping, as well as other relevant procedures.